Role of Steel Castings Manufacturers in USA in Renewable Energy Projects

Role of Steel Castings Manufacturers in USA in Renewable Energy Projects

Steel castings manufacturers in USA are playing an increasingly vital role in the renewable energy sector. As the world shifts towards more sustainable energy sources like wind, solar, and hydropower, the demand for high-quality steel castings has surged. These components are crucial for building durable and efficient renewable energy infrastructure. The USA’s steel castings manufacturers are meeting this demand by leveraging cutting-edge technologies and expertise to produce the components needed to drive the renewable energy revolution.

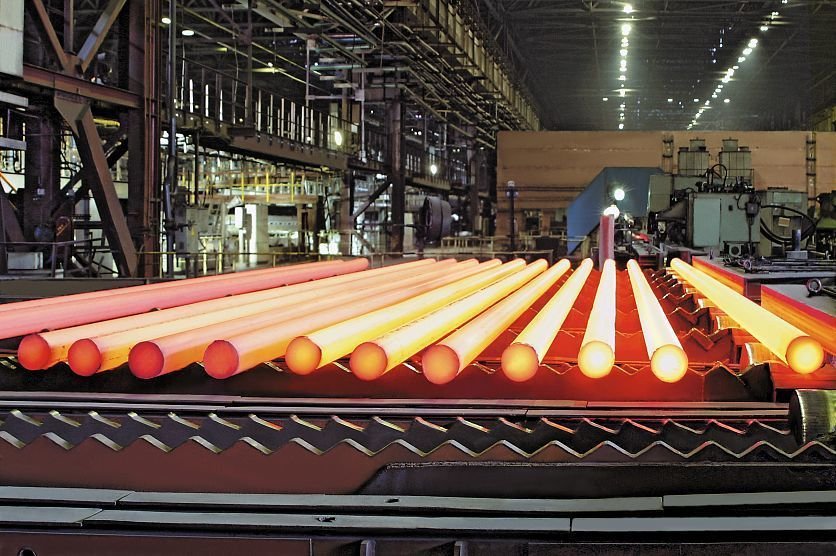

Steel Castings in Renewable Energy Projects

The renewable energy sector relies heavily on steel castings for various critical components, such as wind turbine hubs, solar panel supports, and hydroelectric dam equipment. Steel castings offer the strength and durability needed to withstand the harsh environmental conditions that renewable energy systems often face. In the USA, steel castings manufacturers are using their expertise to produce precision-engineered parts that meet the exacting standards of the renewable energy industry.

In addition to their mechanical properties, steel castings are also favored for their versatility. Steel castings manufacturers in USA can produce a wide range of shapes and sizes, allowing for custom components that fit the unique requirements of different renewable energy projects. This flexibility is particularly important as renewable energy technologies continue to evolve, requiring new and innovative component designs.

Innovation and Technology in Steel Casting

The USA steel castings industry has always been at the forefront of technological innovation, and this is especially true in its contributions to renewable energy. Advanced techniques like 3D printing, computer-aided design (CAD), and automated casting processes have revolutionized the production of steel castings. These technologies allow manufacturers to create more precise, efficient, and cost-effective components for renewable energy projects.

One of the most significant technological advancements is the use of simulation software to optimize casting designs before production begins. This technology enables manufacturers to predict and correct potential issues like porosity or deformation, ensuring higher quality and fewer defects in the final product. By adopting these innovations, Steel castings manufacturers in USA are not only improving the performance of renewable energy systems but also reducing production costs and material waste.

Meeting Environmental Standards

As the renewable energy industry grows, so does the emphasis on sustainability within the manufacturing sector. Steel castings manufacturers in USA are rising to this challenge by adopting eco-friendly practices and reducing their environmental impact. Many manufacturers have implemented energy-efficient production methods, such as using electric arc furnaces, which generate fewer emissions compared to traditional blast furnaces.

Additionally, USA steel castings manufacturers are increasingly using recycled steel in their production processes. This practice not only conserves natural resources but also reduces the carbon footprint of the final product. By aligning their operations with the environmental goals of the renewable energy industry, these manufacturers are contributing to a greener future.

Steel Casting Applications in Wind Energy

Wind energy is one of the fastest-growing sectors in renewable energy, and steel castings play a crucial role in its development. Wind turbines rely on large steel castings for critical components like rotor hubs, nacelles, and base frames. These parts must be incredibly strong and durable to withstand the high stresses and environmental conditions that wind turbines face.

USA steel castings manufacturers are at the forefront of producing these essential components, ensuring that they meet the stringent requirements of the wind energy industry. By using advanced casting techniques, these manufacturers are able to produce components that not only enhance the performance of wind turbines but also extend their operational lifespan, making wind energy a more viable and cost-effective option.

The Role of Steel Castings in Hydropower

Hydropower is another renewable energy source that benefits greatly from the expertise of USA steel castings manufacturers. Hydroelectric dams and turbines require large, complex castings to function effectively. These components must be able to withstand the high-pressure environments found in hydropower systems, making steel the material of choice.

In the USA, steel castings manufacturers are producing components such as turbine housings, guide vanes, and runner blades that are essential for the efficient operation of hydropower plants. By ensuring the durability and precision of these parts, manufacturers are helping to make hydropower a reliable and sustainable energy source with the help of machines and software.

Steel Castings in Solar Power

While solar power is often associated with silicon-based technologies, steel castings still play a vital role in the infrastructure that supports solar energy systems. Solar panel mounting structures, for instance, require steel castings for their frames and supports. These components must be strong enough to hold the weight of solar panels while withstanding environmental factors like wind, rain, and snow.

Steel castings manufacturers in USA are producing these critical components with precision and durability, ensuring the long-term stability of solar energy installations. By providing high-quality steel castings, these manufacturers are helping to make solar power a more efficient and accessible renewable energy source.

Conclusion:

The role of Steel castings manufacturers in USA is becoming increasingly important as the renewable energy sector expands. Through innovation, precision engineering, and a commitment to sustainability, these manufacturers are providing the components necessary to drive the growth of renewable energy technologies like wind, solar, and hydropower. By producing high-quality steel castings that meet the rigorous demands of the renewable energy industry, these manufacturers are helping to shape a greener, more sustainable future.

FAQs:

Q1: What are steel castings, and why are they important in renewable energy?

Steel castings are components made by pouring molten steel into a mold and allowing it to solidify. They are crucial for renewable energy projects because they provide the strength, durability, and flexibility needed for various applications like wind turbines, hydroelectric dams, and solar panel supports.

Q2: How are USA steel castings manufacturers contributing to sustainability?

Many Steel castings manufacturers in USA are adopting eco-friendly practices, such as using recycled steel and energy-efficient production methods. This reduces the environmental impact of their operations and aligns with the sustainability goals of the renewable energy sector.

Q3: What role do steel castings play in wind energy?

Steel castings are essential for producing key components of wind turbines, such as rotor hubs and base frames. These parts must be strong and durable to withstand the stresses and environmental conditions of wind energy systems.

Q4: How do technological advancements benefit Steel castings manufacturers in USA?

Technological advancements like 3D printing, CAD, and automated casting processes allow steel castings manufacturers to produce more precise, efficient, and cost-effective components. These innovations improve the quality of renewable energy infrastructure.

Q5: What industries benefit from USA steel castings manufacturers?

In addition to renewable energy, industries like automotive, aerospace, and heavy machinery also benefit from the high-quality steel castings produced by USA manufacturers. However, their role in renewable energy projects is increasingly significant.